LZS600 Pavement Hydraulic Cold Asphalt Recycling Equipment

The LZS600 Type Pavement Hydraulic Cold Asphalt Recycling Equipment is a versatile and high-efficiency cold recycling machine designed for asphalt concrete recycling. As a leading Cold Recycling Machine Manufacturer, we offer this reliable equipment ideal for both urban and rural road construction and maintenance.

With multi-system auto control capacity, our cold recycling machine can automatically perform asphalt pavement recycling operations. This machine has been widely used in the reconstruction of the old asphalt roads and favorable effect has been gained. Users call it “big brother” of cold recycling machines.

Functions

- Asphalt Pavement Milling & Recycling:

Primarily used for milling old asphalt pavements and performing milling-mix recycling with added materials like water, asphalt, and other recycling agents. - On-Site Stabilized Soil Mixing:

Ideal for mixing stabilized soil for subgrades and subbases in highways, urban and rural roads, airports, ports, parking lots, and building foundations. - Versatile & Compact Design:

Features a compact, flexible design based on advanced technology, capable of various functions including pavement breaking, material milling and crushing, material mixing, and spraying of water, emulsified asphalt, cement slurry, and asphalt recycling agents.

Advantages:

Cold recycling machines enable on-site material mixing, reducing construction time and lowering costs. By recycling asphalt, they save on material expenses during road construction and maintenance while protecting the roadbed. These machines are environmentally friendly, efficient, and easy to operate, with fast travel speeds and minimal maintenance, making them ideal for large projects.

SPECIFICATIONS

| Name | Unit | LZS600 |

| Technical Parameters of the complete machine | ||

| Max. milling & mixing width | mm | 2450 |

| Max. milling & mixing depth | mm | 450 |

| Working speed | m/min. | 0-2.7 |

| Traveling speed | m/min. | 0-10 |

| Rotor diameter | mm | 1380 |

| Rotor rotating speed | r/min. | 125-179 |

| Ground clearance | mm | 400 |

| Minimum turning radius | mm | 7500 |

| Grade ability | % | 30 |

| Transportation clearance (L*W*H) | mm | 8800*3246*3400 |

| Total weight | kg | 30000 |

| Engine (CUMMINS) | ||

| Type of engine | KTA19-C600 | |

| Rated power | KW/HP | 448/610 |

| Max. output torque | N.m | 2237 |

| Rated rotating speed | r/min. | 2100 |

| Min. fuel consumption | g/KW.h (1500r/min.) | 204 |

| Start-up mode | 24V electrical start | |

| Cooling method | Water cooling | |

| Engine oil capacity | L | 47 |

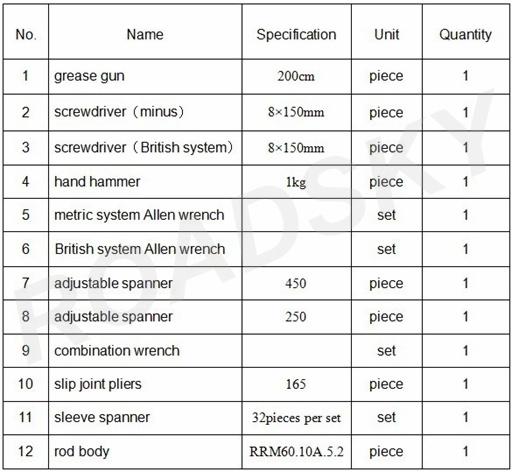

Accessories and Tools List

SPARE PARTS

LZS450 Hydraulic Cold Mix Asphalt Road Reclaimer

Specifications:

| Name | Unit | LZS450 |

| Total weight | Kg | 21000 |

| Size (L*W*H) | Mm | 9490*3014*3400 |

| Ground clearance | Mm | 400 |

| Wheelbase | Mm | 5650 |

| Minimum turning radius | Mm | 7500 |

| Ground angle | º | 16 |

| Max. grade ability | % | 35 |

| Working speed | km/h | 0-2.7 |

| Traveling speed | km/h | 0-19 |

LZS1000 Type Hydraulic Cold Mix Asphalt Road Reclaimer

Specifications:

| Name | Unit | LZS1000 |

| Total weight | Kg | 38000 |

| Size (L*W*H) | Mm | 10423*3380*3330 |

| Ground clearance | Mm | 410 |

| Minimum turning radius | mm | 8800 |

| Max. grade ability | % | 30 |

| Max. milling & mixing width | mm | 2500 |

| Max. milling & mixing depth | mm | 480 |

| Working speed | km/h | 0-2.9 |

| Traveling speed | km/h | 0-12.3 |

Working On-Site: